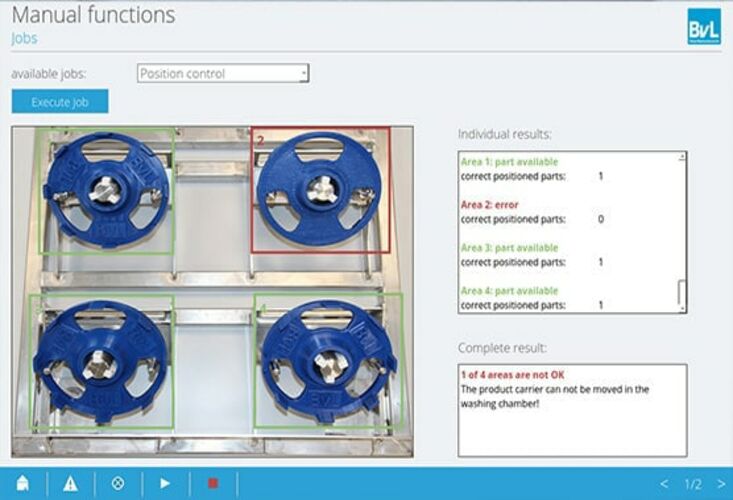

Component monitoring and control

Focus on the essential: your component

The reliable cleanliness of your individual components is essential for ensuring the required process reliability. Our Smart Cleaning solutions for component monitoring and control offer various options for adapting to your application. These include mobile checks for film-type contamination, automatic workpiece detection or component position monitoring for perfect cleaning.