Reliable parts cleaning for safety-critical applications

In commercial vehicles and the armaments and defence industry

In safety-critical sectors such as the commercial vehicle industry and the armaments and defence industry, the highest demands on the technical cleanliness of components are essential. Even microscopically small particles or filmy contamination can impair the function of safety-relevant components and lead to system failures. This is where industrial cleaning systems of the highest quality and reliability are required.

Reliable parts cleaning for safety-critical applications

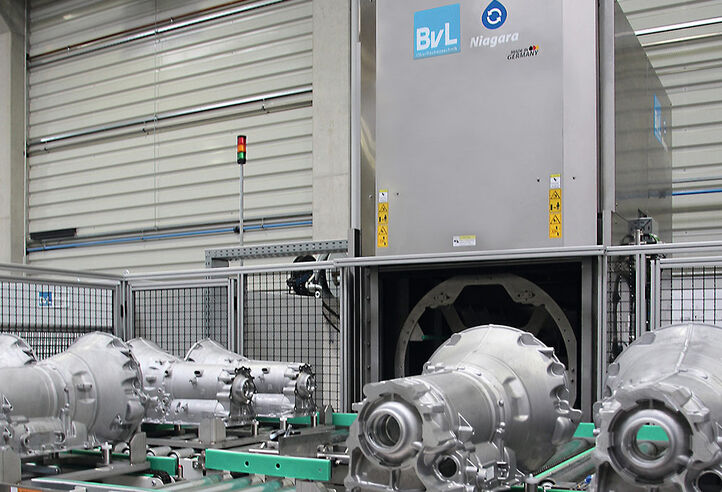

Residue-free, reliable and documentable parts cleaning is essential, especially for safety-critical components - for example in the manufacture of military vehicles, engine parts or electronic components. BvL Oberflächentechnik GmbH, based in Emsbüren, has been developing and producing industrial cleaning systems that meet these high requirements since 1989. The cleaning systems guarantee a consistently high cleaning quality with maximum process reliability, even in 24/7 operation, and are technologically leading and almost limitlessly adaptable in terms of customizability, automation and process integration. They are at the forefront of technology and can be adapted almost limitlessly in terms of customization, automation and process integration. This makes them the ideal solution for demanding applications both in the commercial vehicle sector and especially for companies in the defence industry. Experience from the commercial vehicle industry underlines this expertise: components such as crankcases, cylinder heads, transmission parts and drive shafts have already been successfully cleaned - often using fully automated systems that are integrated into complex production lines.

Certifications and reliability as a crucial basis for partnerships in safety-critical industries

In these industries, sustainable quality, seamless information security and stable, reliable processes are essential. Companies from these sectors - including OEMs and suppliers - need partners who not only bring technological expertise to the table, but also create trust through verifiable standards and reliable processes.

Certifications such as ISO 9001 (quality management), ISO 14001 (environmental management), VDA 6.4 (automotive production equipment) and compliance with the German Water Resources Act (WHG) form an essential basis for this. The TISAX label also confirms compliance with defined requirements in the area of information security - a key aspect when handling sensitive project data.

BvL Oberflächentechnik GmbH fulfills these requirements comprehensively. As a certified specialist company with many years of technical expertise and a clear commitment to Germany as a manufacturing location, BvL is a reliable partner for companies that place particular value on quality, integration capability and safety standards.

BvL's cleaning systems can be precisely tailored to specific components and processes - from pre-cleaning to intermediate and final cleaning - and therefore enable precise and reliable integration into demanding production environments.

The product range includes pass-through, turntable, basket washing and rotary transfer systems as well as immersion cleaning systems and large parts systems. In addition to low-pressure processes, high-pressure processes are offered for cleaning, deburring and paint stripping of various components. The systems are capable of efficiently cleaning even components with special dimensions and the highest levels of soiling. It does not matter what material the components are made of or what their properties are.

As part of a traditional family business with roots dating back to 1860, the fifth-generation owner families stand for technical excellence, innovative strength and absolute reliability. The company currently employs around 170 people. In export, BvL has a strong market position and a comprehensive sales and service network in 20 countries.

Further information

Further information on industrial cleaning for military components and systems can be found here: https://www.bvl-cleaning.com/en/industries/defence

The needs analysis tool can be used to determine the right cleaning system for the respective application Requirements analysis | BvL Cleaning

Contact

BvL Oberflächentechnik GmbH

Grenzstr. 16

48488 Emsbüren

Phone: 05903 951-60

Fax: 05903 951-90

info@bvl-group.de

www.bvl-group.de

Press release

Christine Brühöfner

Marketing

Phone: 05903 951-509

Fax: 05903 951-90

christine.bruehoefner@bvl-group.de