Persistent contaminants, such as shavings/filings, welding residues, silicates, etc. can be loosened effortlessly with high force.

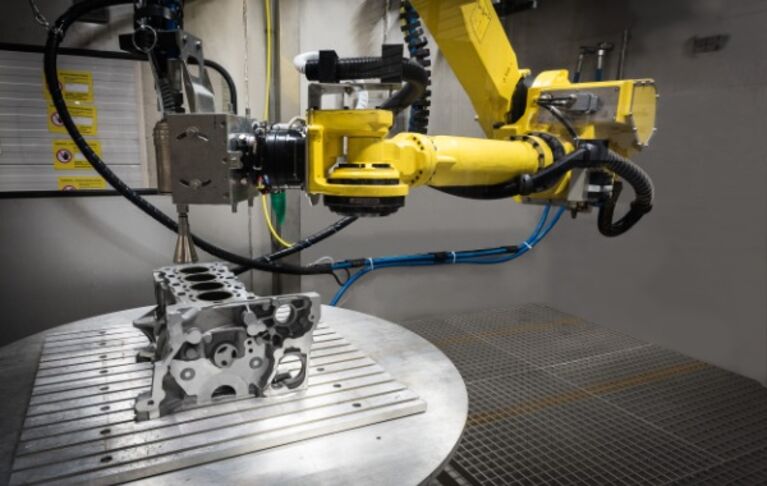

High-pressure deburring

Machining burrs, casting flakes and shavings/filings can be reliably removed – even from workpieces with technically complex geometries. The high-pressure jet is directed at the critical points of the component so that even those components with deep or small holes, blind holes and undercuts can be deburred with ease thanks to the high kinetic energy of the jet.

- variable pressure range allows for different applications

- robot system for maximum flexibility

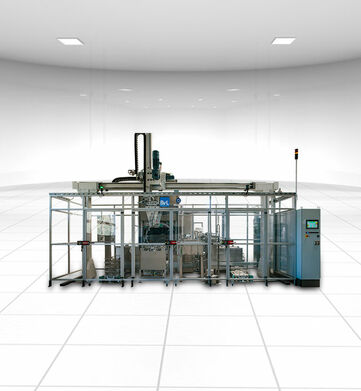

- can be combined with precleaning, fine cleaning, drying and cooling

| GeyserVM | high-pressure supply module |

| Pump unit: | frequency-controlled high-pressure pump; variable pressure pump |

| Equipment enclosure: | integrated pre-pressure pump, filtration system and high-pressure pump |

| Circuit cooling: | cooling of the high-pressure pump via a heat exchanger |

| Supply: | from the cleaning system tank or optionally via an integrated storage tank |

| Housing: | complete stainless steel housing including the floor pan |

| Control and operation: | Siemens Simatic with Siemens touch panel |

| Geyser AE | high-pressure work unit |

| Processing chamber: | high-pressure unit integrated into the wet cell |

| Water tools: | specifically aligned nozzles, multiple rotating nozzles or individual lances changeable tools for various different applications |

| Workpiece guidance: | nozzle guided to workpiece or workpiece guided to water tool integrated, water-proof robots (optional) |

| Integration: | can be combined with pre-cleaning, subsequent fine cleaning, drying and cooling |

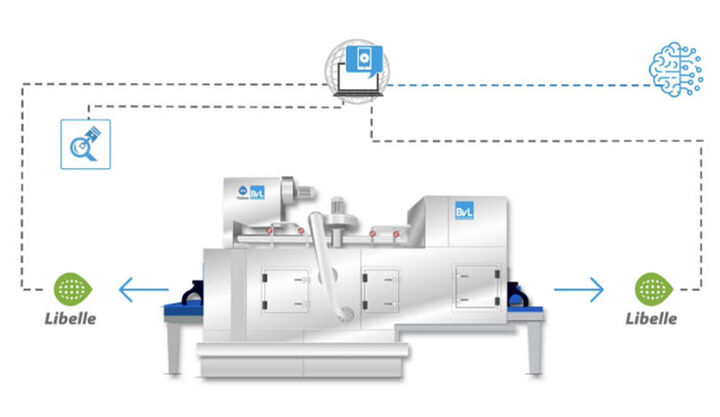

Media supply

- Cleaning medium passes through a circuit or the waste water process

- Absolute reliability thanks to filter technology

- High-pressure processes in a wet cell

Advantages

- Robot technology (optional) offers maximum flexibility for the range of movement, conversion, as well as changing processing sequences and new geometries

- No thermal or mechanical strain on the components

- High efficiency thanks to short cycle times

Technology in detail

Technical Data

| Example: Technical data | Unit | for the BvL demonstration system Geyser | ||||||

| Usable length | mm (in) | 800 (31) | ||||||

| Usable width | mm (in) | 600 (24) | ||||||

| Usable height | mm (in) | 400 (16) | ||||||

| Load capacity | kg (lb) | 50 (110) |

Other technical data and on-site services on request