High Purity Cleaning at Grade 1 and Grade 2 level

BvL Atlantic immersion cleaning system fulfils the highest requirements of the semiconductor supply industry

Emsbüren, May 2025 - In April, targeted test washes for the high purity industry took place in our in-house Technology Center. The clear goal: to clean components from semiconductor production - especially those used in ultra-high vacuum (UHV) environments - to at least Grade 2 level. The result confirms this: The Atlantic immersion cleaning system from BvL Oberflächentechnik GmbH fully fulfils the demanding requirements of the semiconductor supply industry.

The components used were made of titanium and aluminium with complex geometries such as undercuts and capillaries - a real challenge for any cleaning solution. Atlantic mastered this task with aplomb.

Technical concept and process design

The Atlantic has a total of nine process stations: seven cleaning and two drying tanks. It therefore offers the perfect combination of efficiency, process reliability and flexibility - precisely tailored to the needs of Clean Service Providers (CSP).

The system is equipped with state-of-the-art technology, including ultrasonic modules with 40 kHz and 75 kHz, HEPA H13-filtered hot air and vacuum drying, ultra-fine filtration, continuous pH and conductivity monitoring and freely programmable cleaning sequences. The cleaning process itself took place in cleaning baths prepared with demineralised water - with both alkaline and acidic cleaning agents. The subsequent rinsing processes, crucial for high purity applications, were carried out with tap water and ultra pure water (UPW).

The UPW used was provided by an EnviroFALK ultrapure water treatment system. This is equipped with components such as particle filtration, softening, reverse osmosis, UV sterilisation, ion exchange, nano-ultrafiltration and TOC measurement. With a treatment capacity of 300 litres per hour, excellent water values were achieved:

Conductivity: 0,06 µS/cm

TOC value: 13,58 ppb

Validated results in the high purity sector

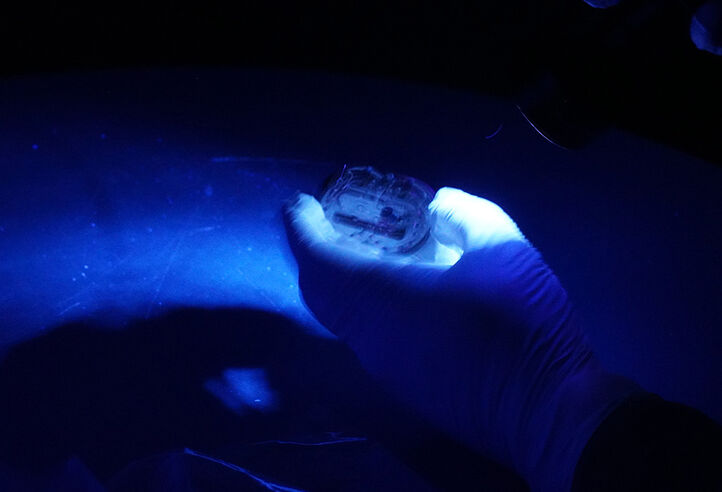

Initial visual inspections were carried out in the company's own dark room before and after cleaning. The components were analysed for particles and stains using UV and Bright Light. The results were then confirmed in the laboratory and document the high performance of the Atlantic system:

Particle Measurement (PMC) - goal: Grade 1

≥ 0.5 μm: 650,000 particles/m² (specification: 2,000,000)

≥ 5.0 μm: 17. 000 particles/m² (specification: 20,000)

≥ 10.0 μm: 0 particles/m² (specification: 1,000)

Outgassing rates for Residual Gas Analysis (RGA) - goal: Grade 2

H₂O: 2.71E-4 mbar-l/s

CₓHᵧ v: 2.53E-7 mbar-l/s

CₓHᵧ nv: 2.80E-8 mbar-l/s

The desired atomic-percentage loads on HIO elements or elemental surface contamination can also be achieved in the cleaning process.

Customised cleaning - with full dedication to the process

As an experienced special machine manufacturer, BvL Oberflächentechnik GmbH offers customised cleaning systems of the highest quality. The Atlantic, for example, is modularly configurable and can be customised exactly to your requirements: from the choice of suitable materials (e.g. HIO-free) to the cleaning process (e.g. multi-frequency ultrasound) and drying process, right through to the design of the tanks according to your component dimensions.

Family business with tradition and international presence

Since 1989, BvL Oberflächentechnik GmbH has been developing and building innovative cleaning systems for the highest demands - Made in Germany. As a family-run quality supplier with headquarters in Emsbüren, near the Dutch border, we support our customers worldwide through a close-knit network of service branches. Development and production take place entirely in Germany - for the highest quality, precision and reliability.

Planning a New Project?

Talk to us—we’re happy to provide personalized and confidential advice.

Use our requirements analysis tool to find the perfect solution for your application.

Contact:

BvL Oberflächentechnik GmbH

Grenzstr. 16

48488 Emsbüren

Tel.: +495903 951-60