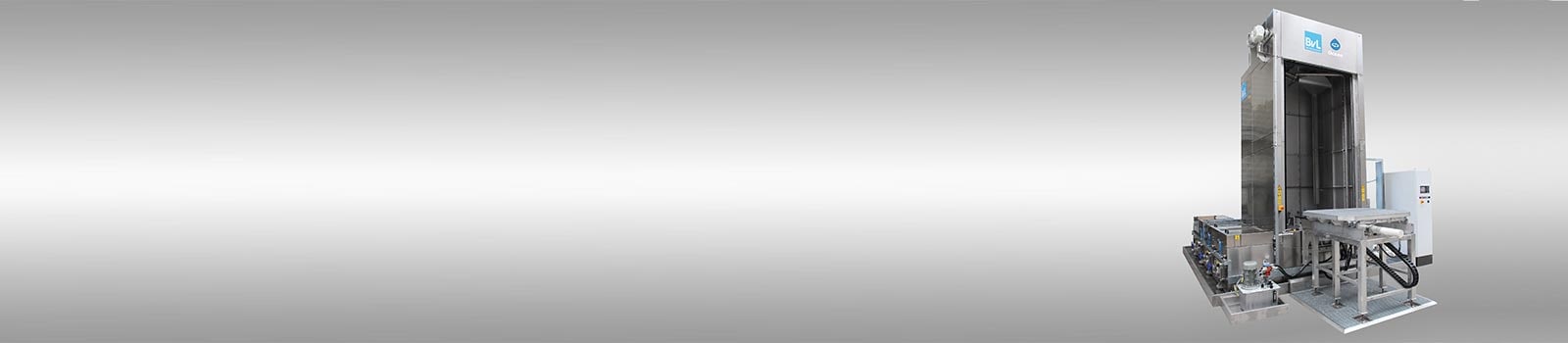

Hardening frame with high weight and large dimensions

All-around cleaning with high volumetric flow before nitrating and gearwheels on a hardening frame with high load capacity and large circumference.

U-shaped special nozzle system with flat spray nozzles

This cleaning principle allows efficient and economical cleaning with a low investment volume. The usable height of the cleaning chamber was specially adapted to high components and the number of nozzle rows was individually tailored to the application.