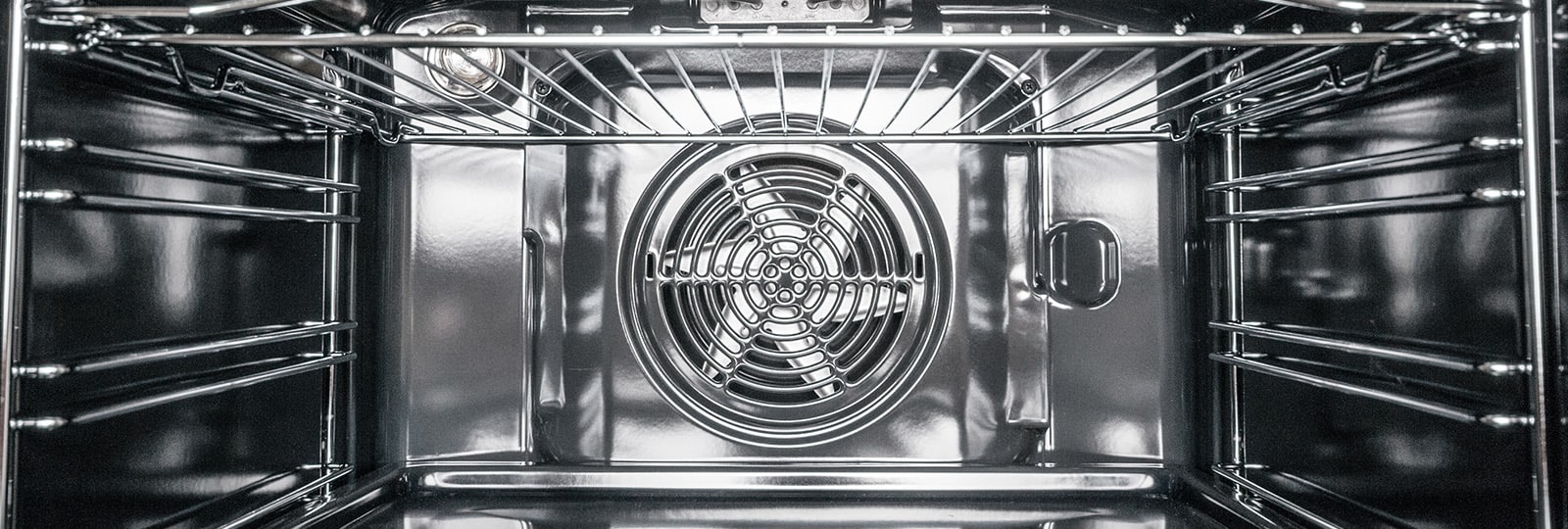

Cleaning solutions for household appliances

Grease and stain free: Technical cleanliness in preparation for further processing household appliances.

Perfectly integrated into your production process

Our cleaning system integrates seamlessly with your production process: your internal processes determine the configuration of the system. When manufacturing household appliances and cookware, high throughputs and continuous conveyor technology often determine the production sequence, which we address with our BvL cleaning system.