Your demand: Cleaning with a focus on quality

- Securing production quality

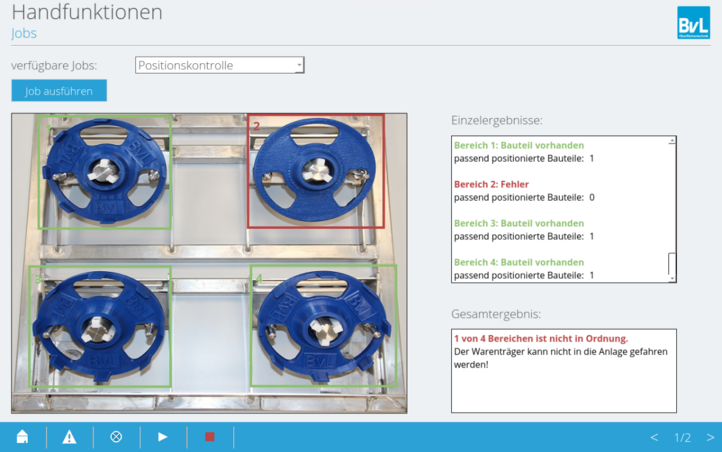

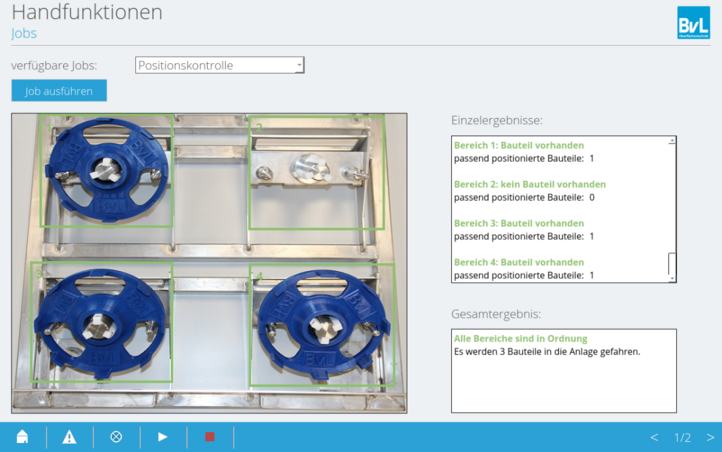

- Correct positioning of the components in the parts carrier

- Reliable cleaning results

- Documentation of the components before and after cleaning

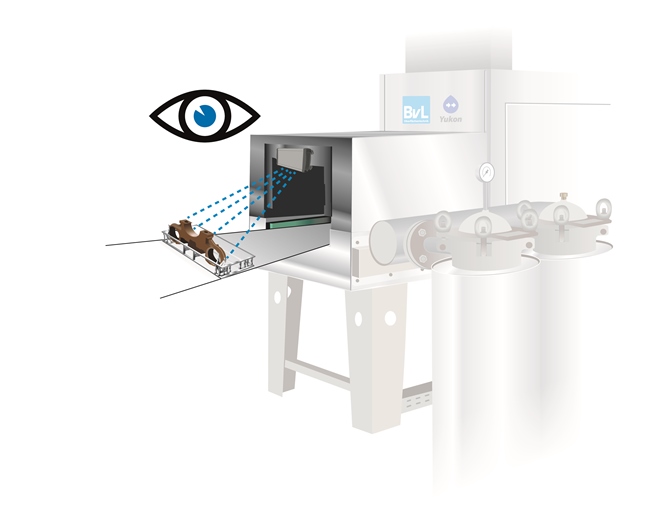

Component monitoring before and, if necessary, after cleaning:

Individual teaching process: