Efficient cleaning of converter components: Yukon

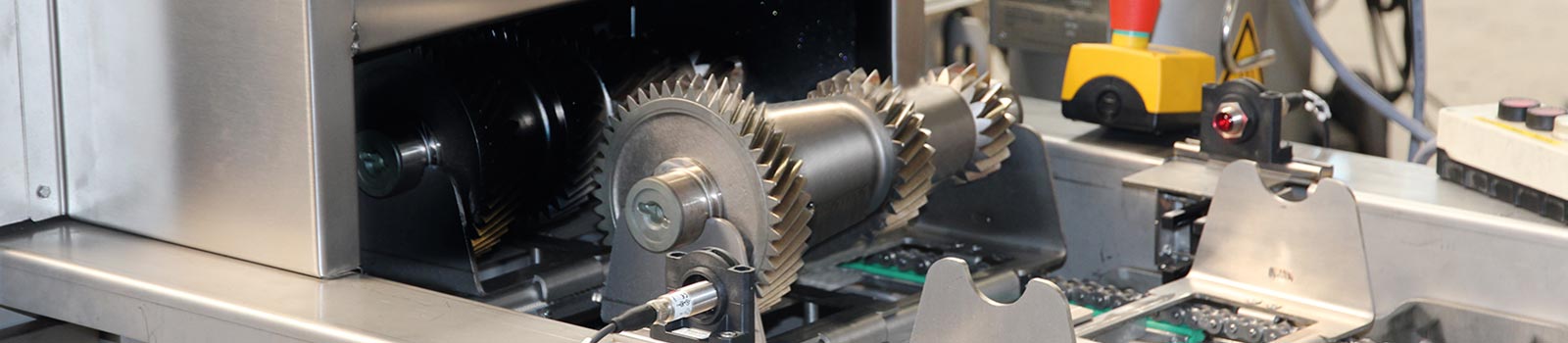

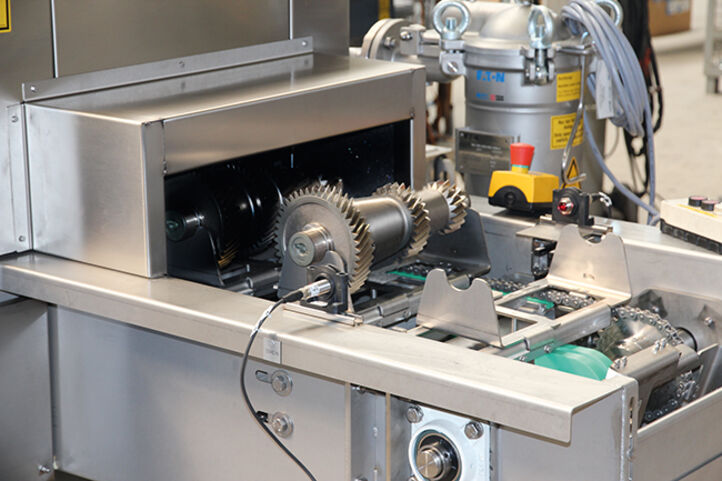

The washing unit integrates seamlessly into the production line (one-piece-flow) with the parts sorted and fed into the system via multiple lanes that can be operated separately from one another at different speeds.