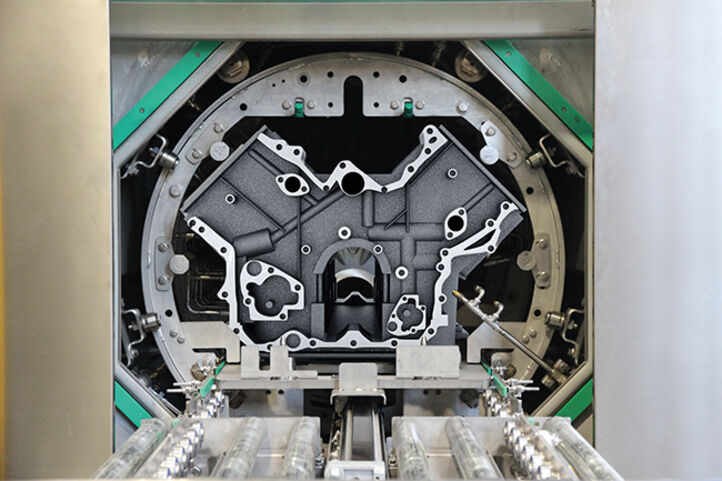

Targeted external and internal cleaning of cylinder blocks and cylinder heads: Niagara

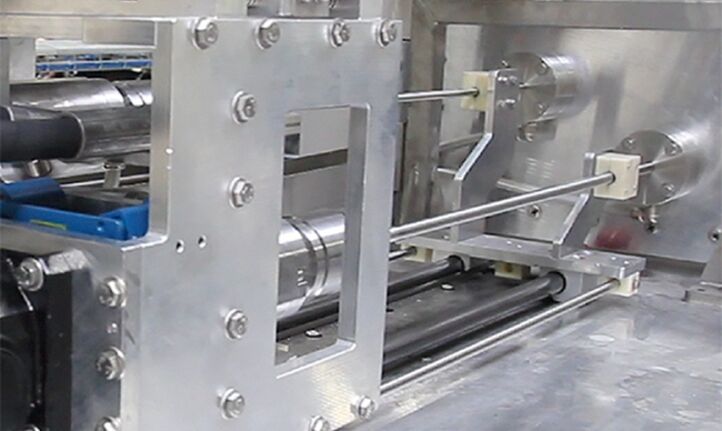

Various different parts with deep-set and hard-to-reach holes and supply lines (oil, air, water and fuel ducts) can be cleaned in one washing chamber. The parts holders are scanned using bar codes and the corresponding washing program is automatically selected. The vacuum drying stage integrated into the washing chamber and the subsequent external cooling phase guarantee seamless further processing in downstream production processes.