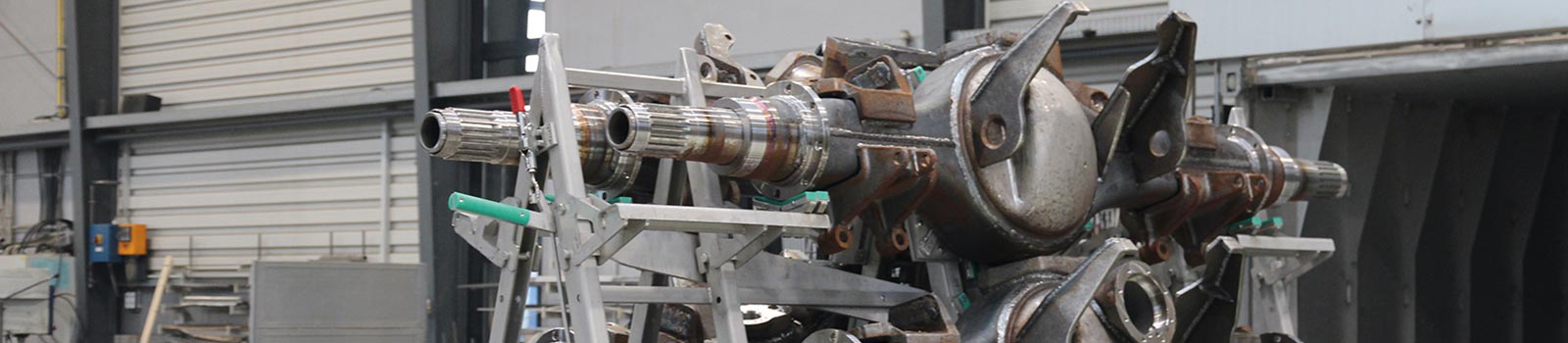

Intelligent cleaning system for axle housings

Special lance technology for complex internal geometries:

A lowering lance bell moves into the component for targeted removal of particles from blind holes and on the shell surface.

Artificial intelligence for component identification:

The BvL Libelle Product Control monitors and evaluates the components after cleaning. It shows the result in an app and informs the operator which storage location to use.