Industrial Cleaning Systems for Safety-Critical Components in the Commercial Vehicle Sector:

Top Quality and Reliability „Made in Germany"

Since 1989, our company, BvL Oberflächentechnik GmbH, has been developing and manufacturing high-quality industrial cleaning systems at its site in Emsbüren, Germany. As part of a traditional family-owned enterprise with roots dating back to 1860, the fifth generation of the founding families stands for technical excellence, innovation, and absolute reliability.

Our product range covers the entire spectrum of aqueous-based industrial parts cleaning. It makes no difference what material your components are made of or what their geometry is—our professional cleaning systems can handle even special dimensions and the most challenging contaminations. We currently employ around 170 people. In the export market, we have established a strong international position, supported by an extensive sales and service network in 20 countries.

Our range of cleaning systems includes inline, rotary table, basket washing, and indexing systems, as well as immersion cleaning systems and large-part solutions. In addition to low-pressure systems, we also offer high-pressure processes for cleaning, deburring, and paint stripping of various components.

Reliable Parts Cleaning for Safety-Critical Applications

Our cleaning systems are not only technologically advanced but also highly adaptable in terms of customization, automation, and process integration. This makes them the ideal solution for demanding applications in the commercial vehicle sector as well as for companies in the defense and military industries.

Especially when it comes to safety-critical components—such as those used in military vehicles, engine parts, or electronic systems—a residue-free, reliable, and fully documentable cleaning process is essential. Our cleaning systems ensure consistently high cleaning quality with maximum process reliability, even in 24/7 operations.

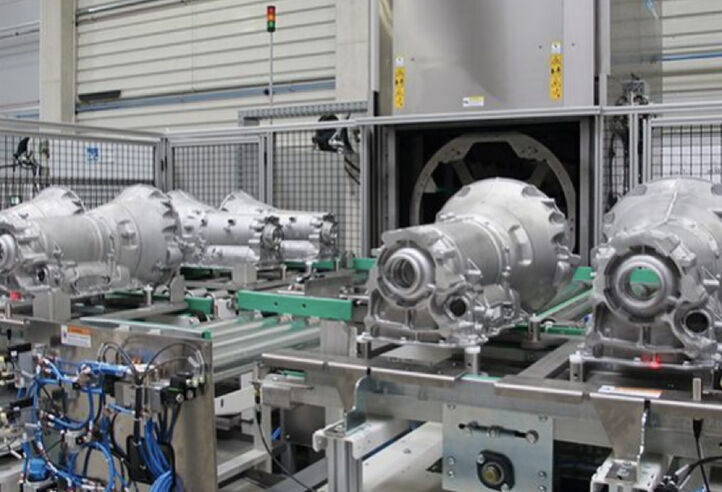

Thanks to our many years of experience with customers in the commercial vehicle industry, we have successfully cleaned components such as crankcases, cylinder heads, transmission parts, and drive shafts. These systems are often fully automated and integrated into complex production lines.

Trust Through Certification and Reliability

For our customers in sensitive industries, we offer not only technological excellence but also maximum security and confidentiality. As a certified specialist company (ISO 9001, ISO 14001, VDA 6.4, WHG) with TISAX labeling for information security, we meet the highest standards in handling confidential project data. Our customers—including OEMs and suppliers—know they can count on us.

With our technical expertise and clear commitment to manufacturing in Germany, we are the ideal partner for companies in the defense and military sectors that value quality, integration capabilities, and reliability. Our systems can be precisely tailored to your components and processes—whether for pre-cleaning, intermediate cleaning, or final cleaning.

Planning a New Project?

Talk to us—we’re happy to provide personalized and confidential advice.

Use our requirements analysis tool to find the perfect solution for your application.

Contact:

BvL Oberflächentechnik GmbH

Grenzstr. 16

48488 Emsbüren

Tel.: +495903 951-60

info@bvl-group.de

www.bvl-group.de