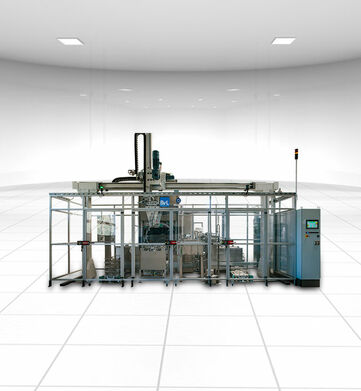

High Purity Applications

The Atlantic reliably meets the demanding cleaning requirements of industries such as the semiconductor industry – particularly ultra-high vacuum technology – as well as the optical industry, medical technology industry and the cleaning of precision parts. It achieves particulate and molecular cleanliness at least at the Grade 2 level, typical for ultra-high vacuum applications, up to the Grade 1 level.

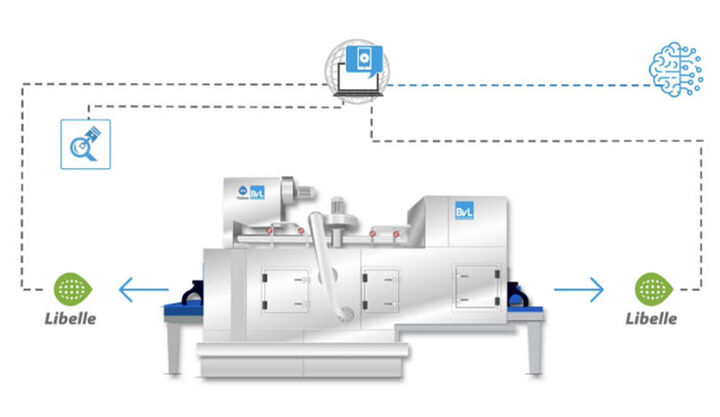

Variable loading and discharging stations for loading and unloading: can be positioned both at the sides and at the front (inline).