- Very high cleanliness requirements: Grade 4 to 1

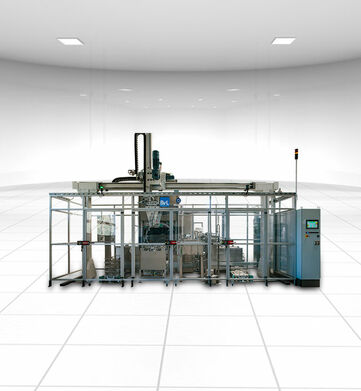

- Compact design for space-saving installation

- Cleanroom integration possible

- State-of-the-art system to prevent recontamination and cross-contamination

- Innovative process: Vacuum Impulse Technology (VIT)

- Modular design: Expansion of tanks and cleaning chambers possible

- Individually selectable program sequences: both process step order and choice of times and parameters

- Flexible use: as pre-cleaner or final washer

- Service-friendly: easy accessibility of tanks and components

| Spray cleaning: | Rotating or swiveling holder system with customized adjustment of the nozzles and nozzle frames |

| Flood cleaning: | Stepless partial flooding, full/vacuum flooding, recirculating flooding |

| Ultrasonic cleaning: | e.g., 40, 80, and 132 kHz, multi-frequency systems, ultrasonic generators with sweep function for delicate geometries |

| Vacuum Impulse Technology (VIT): | special deep cleaning for complex component geometries |

| CleanDesign: | Electropolished surfaces and rounded chamber design to avoid contamination areas |

| Measures for safe process operation: | Automatic chamber cleaning with UPW ultrapure water, rapid complete draining, and further processes to prevent cross-contamination |

| Functional principle: | Rotating ferris wheel system for all-round cleaning |

| Number of tanks: | Modular with single-and multi-tank systems |

| Energy efficiency: | Insulation and intelligent control system |

| Loading: | Front loading via roller-guided holder device |

| Housing: | Modern design made of high-quality stainless steel – front panel with refined surface finishing (optional) |

| Media-carrying components: | Cleanroom-compliant without HIO elements |

| Air filter for chamber ventilation and drying: | HEPA H 13 Filter |

| Control and operation: | Siemens Simatic with modern and userfriendly Siemens touch panel |

Technology in detail

Technical Data

Basic system NiagaraUP - Basket washing systems

| Effective length | mm | 670 | ||||||

| Effective width | mm | 480 | ||||||

| Effective height | mm | 300 | ||||||

| Feed height | mm | 925 | ||||||

| Load capacity / batch | kg | 150 | ||||||

| Tank volume per tank (I / II) | Liter | 620 |

Other technical data and on-site services on request

Processing steps

The cleaning process takes place in a single chamber and can be individually configured in multiple stages:

- Spray cleaning

- Flood cleaning (stepless partial flooding, full/vacuum flooding, recirculation flooding)

- Ultrasonic cleaning (single or multi-frequency systems)

- Innovative BvL vacuum pulse technology (deep cleaning for capillary component structures, boreholes, and internal channels)

- Efficient chamber cleaning with UPW water (ultra-pure water) between treatment steps

- Continuous filtration

- Rapid and complete draining

- Drying process – alternative or combinable: Circulation air, hot air with HEPA H13 filter, infrared drying, vacuum drying

Options and supplements

- Cleanroom option

- Additional tanks and chambers

- Various handling and automation systems

- Cooling and demagnetization systems