Vacuum Impulse Technology (VIT)

Deep cleaning of precision parts

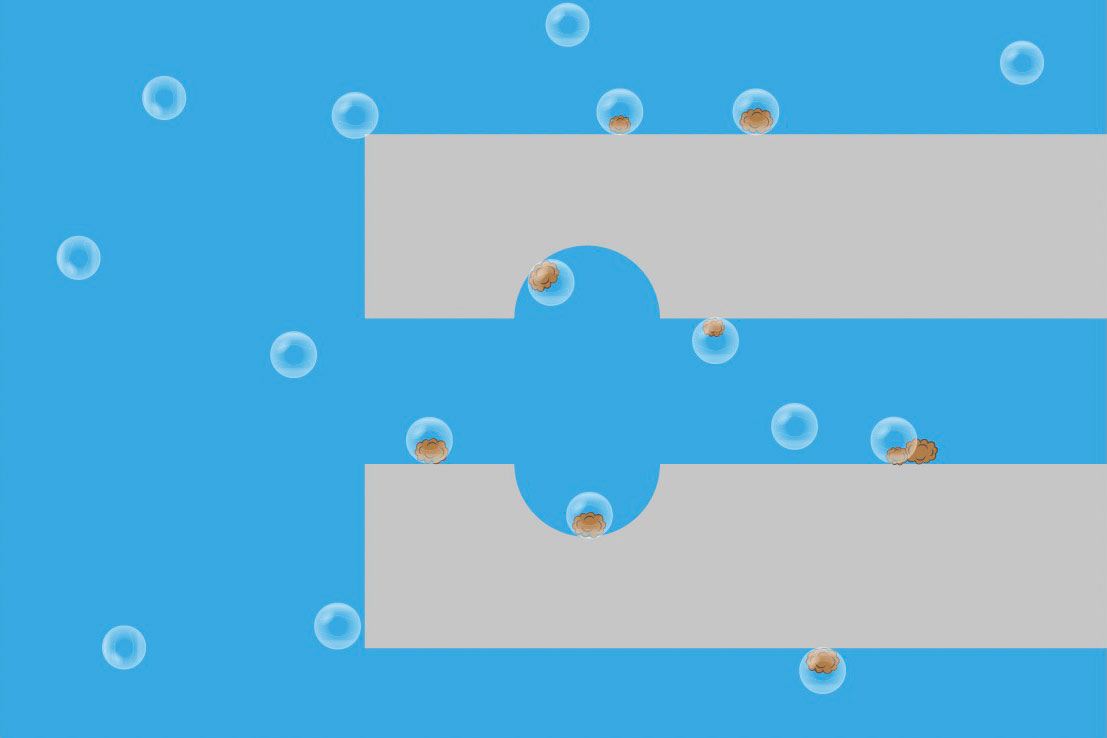

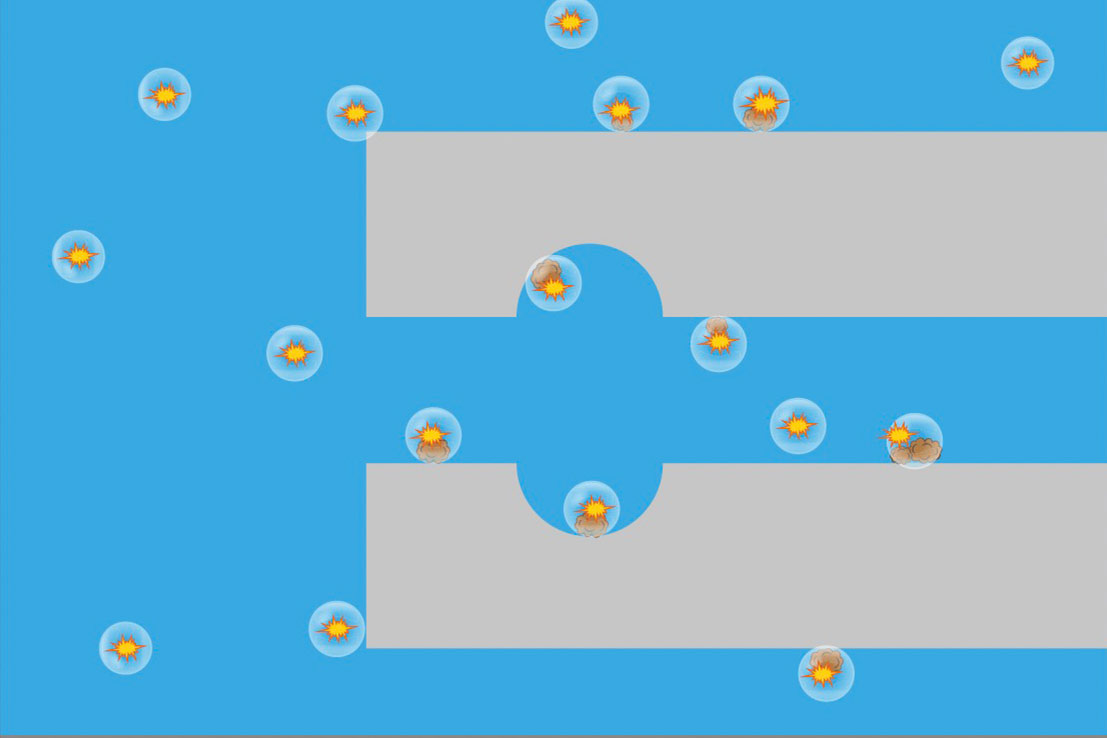

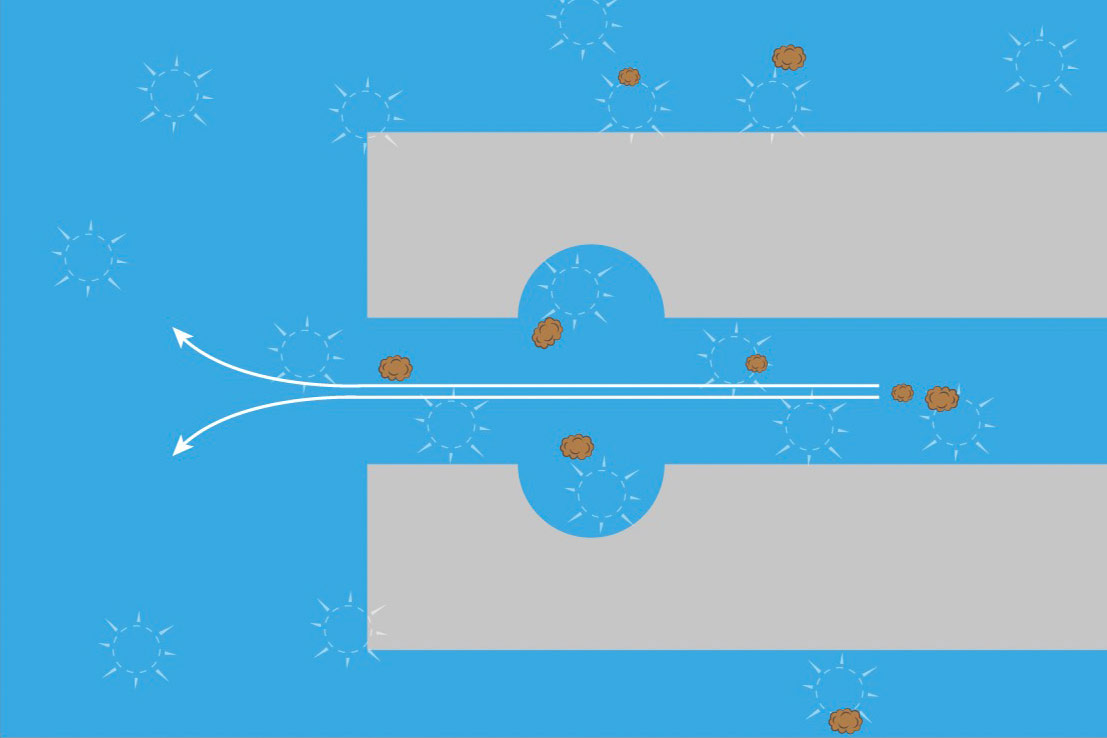

Our innovative pressure change process, Vacuum Impulse Technology (VIT), was developed for industries with the highest requirements for technical cleanliness – often in the micro range down to the molecular level. In these fields, residue-free surfaces are required, with processes that are both validatable and reproducible.

While ultrasonic waves, for example, work excellently in open media, they reach their physical limits in deep bores, tightly packed bulk material, or narrow channels: the waves reflect and lose effectiveness. This is where our Vacuum Impulse Technology comes into play, enhancing the cleaning process with a mechanical depth effect that is effective even where ultrasound cannot reach.

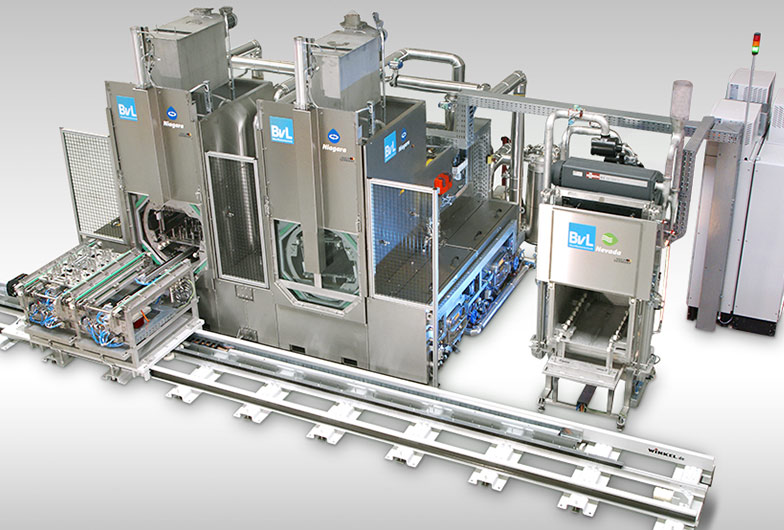

- High purity applications

- Hydraulics and fluid technology

- Automotive industry

- Semiconductor manufacturing

- Medical technology

- Precision parts with internal channels, bores, capillaries