- More

BvL service system

The brain of the intelligent BvL cleaning system

- Stores process data locally, on the company network or in an internet-based solution and makes the data usable

- Individual evaluations can be conducted internally or in collaboration with BvL, so as to ensure an optimum process flow.

All relevant process data, operating states and error messages are stored locally in the Data Logger and optionally in an internet-based solution. The internet-based Fleet Manager enables the user-friendly display and visualization of the data in a web browser on a computer or a mobile device.

Close

Component monitoring Input+Component monitoring Output+Media monitoring+System monitoring +

Component monitoring Input+Component monitoring Output+Media monitoring+System monitoring +Intelligent cleaning

From the beginning

Parameters change regularly during a component cleaning process. That is what makes it so complex.

Challenge

Even the initial states of the components may be very different: the type and degree of soiling or throughput can vary. With each washing cycle, bath soiling increases, while the concentration of the cleaning agent decreases and the filter bags fill up. At the end, however, the cleaning result must be identical.

Solution

Smart Cleaning is a “thinking” cleaning system. System states can be presented in a clearly structured way. The system controls itself.

Benefits

Smart Cleaning makes BvL cleaning systems “intelligent”. The various Smart Cleaning apps show any changes immediately. Sub-processes are self-regulating. These intelligent processes no longer require any user intervention.

Intelligent is also ecological!

Smart Cleaning also means ensuring environmentally friendly cleaning processes. Reductions in energy and water consumption have a very positive effect on life cycle assessments for BvL cleaning systems. Exhaust air management lowers the heat that is output by a continuous system, while drying control reduces the energy input into the drying process.

- Reliable quality and reliable processes

- High plant uptime

- Time- and cost-efficient

- Predictive maintenance

- Energy savings

- Simple operation

Smart Cleaning solutions

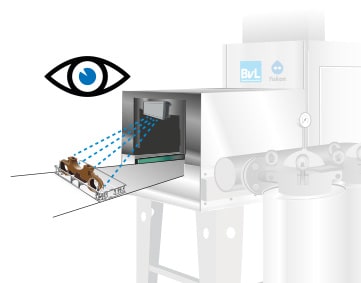

Intelligent cleaning solutions improve the system hardware and the state of the cleaning bath, as well as the component position and workpiece identification. This ensures your cleaning system is fit for the future.

BvL cleaning solutions

with Libelle sensor system

With the Libelle sensor system, BvL has been a pioneer in the area of sensor-based process reliability for many years. The objective is to make the cleaning process simpler and easier to monitor. Libelle sensors allow better monitoring of components, system and media to achieve more reliability in the cleaning process.

Vision 2030:

Self-learning cleaning systems

The smart technology used in BvL cleaning systems is always being improved. Very soon now, these algorithm-controlled systems will not only be capable of detecting problems but will also be able to learn from them.

To ensure stable and efficient cleaning processes, an artificial intelligence unit analyses the product feed state plus washing, system and process parameters, and discharge conditions. This enables the system to react independently to changes and unknown states, and calculate the target discharge condition.

Thanks to their continuous monitoring and adaptation of process parameters, self-learning cleaning systems maintain a higher-quality cleaning process for longer while requiring less resource input and fewer personnel.